The reliable detection of leaks in industrial systems is crucial for work and process safety. The helium and hydrogen leak detectors based on Archigas’ advanced sensor technology offer fast, robust and long-term stable measurements that are specially tailored to the needs of modern industrial applications.

Specific advantages

- Fast response time: identify leaks immediately in up to < 30 ms

- High precision: detection of even the smallest leaks at just a few ppm

- Maximum cost-effectiveness: no complex sample preparation required, therefore cost-efficient integration into existing systems

- Very small design: ideal for automation processes and installation in compact systems

- Special adaptability: suitable for various industrial applications, including automotive, aerospace, energy and manufacturing industries

Why use helium and hydrogen for leak detection?

- High detection accuracy: Helium and hydrogen are ideal tracer gases due to their small molecule size and high diffusion rate, which enables precise localisation of leaks

- Safety: Both gases are non-toxic and non-corrosive, making them safe for use in various environments

- Environmental friendliness: Helium and hydrogen are environmentally friendly gases that have no harmful effects

- Cost savings: The high efficiency of leak detection can reduce operating costs and minimise product losses

Measuring tasks

Helium leakage monitoring: Measuring range: 0 – 100 vol.% He

Monitoring hydrogen leakage: Measuring range: 0 – 100 vol.% H2

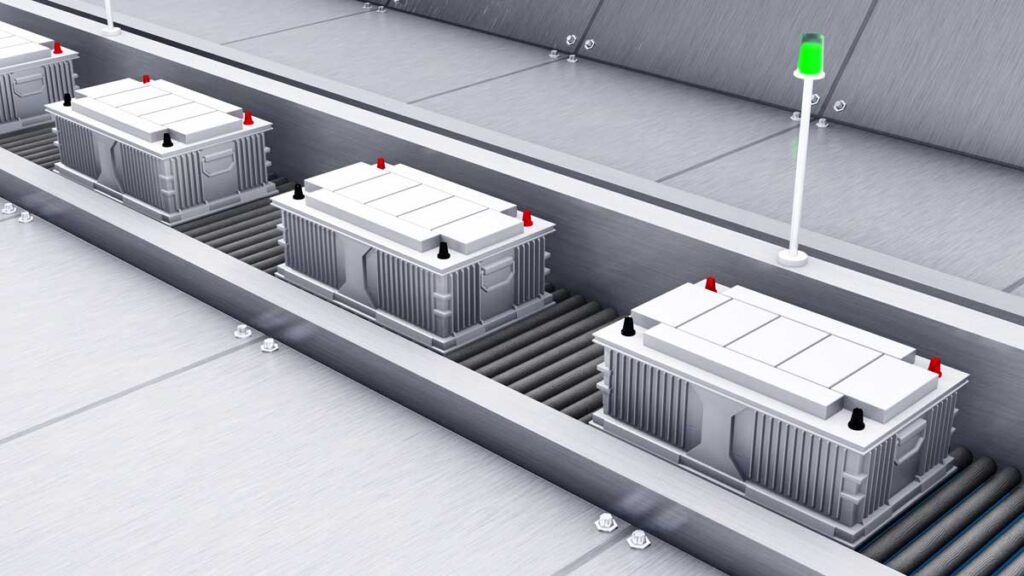

Leakage monitoring in industrial systems: Automotive, aerospace, power generation, manufacturing

Discover other areas of application for Archigas gas analysers

Electrolysis

Monitoring of UEL / LEL and purity, e.g. for H2 electrolysis

Fuel cell

Monitoring the hydrogen concentration in the exhaust gas train

H2 in natural gas

Determination of the hydrogen content in natural gas networks up to 100%

Helium measurement

Fast and precise helium detection without detours

Leak testing

Automated detection of leaks for monitoring

Further areas of application

Purity control, purge gas monitoring, measurement of other binary or quasi-binary gas mixtures