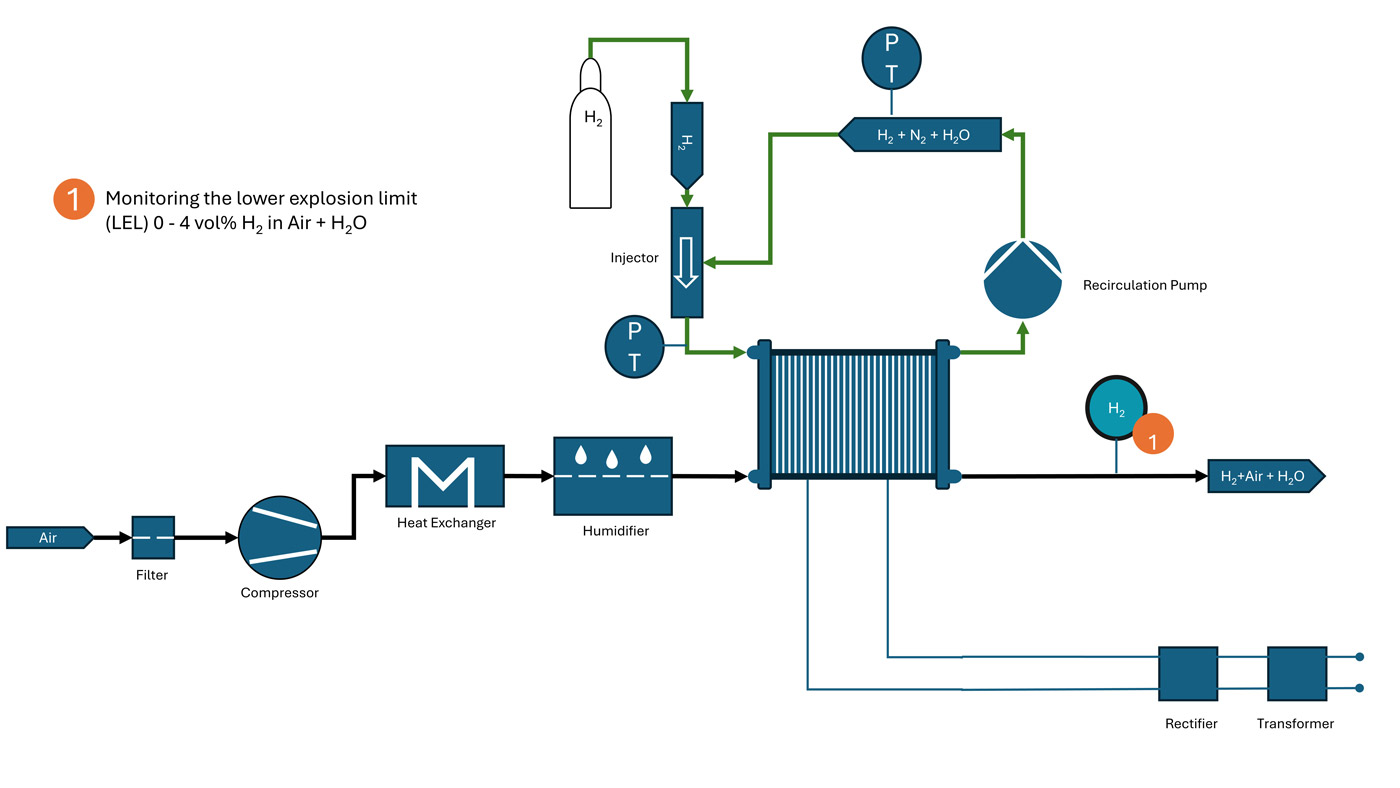

Consistent monitoring of hydrogen is also crucial for the efficiency and safety of fuel cells. Archigas’ advanced sensor technology enables particularly accurate and fast measurements that meet the specific needs of users. It can be used to optimise the performance of fuel cells and meet the highest safety standards.

Specific advantages

- High precision and speed: with a wide measuring range from a few ppm up to 100 vol.% and response times down to <30 ms, optimally designed for fuel cells

- Particularly robust: resistant to condensate and water and suitable for pressures up to 200 bar

- Maximum safety: reliable monitoring of explosion limits to increase occupational safety

- Adaptability and cost-effectiveness: versatile measurement solutions without additional sample preparation, cost-efficient and space-saving

Challenges in H2 measurement in fuel cells

- Moisture in the process gas destroys devices and falsifies measurements

- Cross-sensitivity compensation or dehumidification of the gas required

- Reaction times (t90) should be short and require complex sample preparation

- High operating pressures and process temperatures require additional sample preparation

Mastered by Archigas H2 gas analysers

Sensors are not destroyed by contact with condensate

Cross-sensitivity of the humidity is significantly reduced

Response times are only up to <30 ms

Pressures of up to 200 bar are permissible

High corrosion resistance is available

Continuous online quality monitoring up to H2 4.0 (99.99%) possible

Process temperatures of the gas can be up to 130°C

Additional costly sample preparation is not required

Discover other areas of application for Archigas gas analysers

Electrolysis

Monitoring of UEL / LEL and purity, e.g. for H2 electrolysis

Fuel cell

Monitoring the hydrogen concentration in the exhaust gas train

H2 in natural gas

Determination of the hydrogen content in natural gas networks up to 100%

Helium measurement

Fast and precise helium detection without detours

Leak testing

Automated detection of leaks for monitoring

Further areas of application

Purity control, purge gas monitoring, measurement of other binary or quasi-binary gas mixtures